Once you have assembled your tools and ingredients you are ready to make your first batch of natural lye soap. At this point you need to have a simple recipe picked out. You will also need the oils that the recipe requires. You should also have your work area set up and your lye purchased and present. Follow all safety procedures for working with lye. Wear goggles and gloves.

Making Soap from Scratch at Home

Step One – Prepare your molds. Molds can be anything from a greased pan to capped pvc pipes. If you want small hand soaps you can use candy molds. To make a loaf of soap you can make a wooden mold and line it with plastic. Then you would slice it after it cured. For molds, plastic, glass or stainless steel is recommended. Place your molds on a flat, level surface and grease them with an oil like PAM. Make sure you have enough capacity to accommodate all of your soap mix. If you have extra soap mixture and no place to put it then it would go to waste.

Step One – Prepare your molds. Molds can be anything from a greased pan to capped pvc pipes. If you want small hand soaps you can use candy molds. To make a loaf of soap you can make a wooden mold and line it with plastic. Then you would slice it after it cured. For molds, plastic, glass or stainless steel is recommended. Place your molds on a flat, level surface and grease them with an oil like PAM. Make sure you have enough capacity to accommodate all of your soap mix. If you have extra soap mixture and no place to put it then it would go to waste.

Step Two – Measure out your water and lye. Use a postal or digital scale for weight. Remember to zero out the scale with your empty container on it so you get the weight of the lye and water only. Once you have the exact amounts, dissolve the lye in cold water (Do not use an aluminum container. Use stainless steel, enamel coated steel or a heat resistant glass container like Pyrex). Do NOT pour water into the lye. Pour the lye slowly into the water just a little at a time. Stir until the lye is dissolved and let the solution cool. The water will become very HOT in a matter of seconds after stirring in the lye. This is normal. Now, allow the lye/water solution to cool to around 110 degrees. At this point it will be clear.

Step Three – Measure, Mix and Melt the oils and fats and let them cool gradually to around 110 degrees. The heating is mainly done to melt fats that are in solid form like lard. If your oils are already in liquid form such as canola oil or corn oil just heat them up to around 110 degrees. Check to make sure that the container you are using to heat the oil is is large enough to hold the oil plus the lye solution with enough room left over for stirring without splashing the solution everywhere. If you would like, you can use a separate container for mixing the oil and lye together. If you do this simply pour the warmed oil into this container prior to step 4.

Step Three – Measure, Mix and Melt the oils and fats and let them cool gradually to around 110 degrees. The heating is mainly done to melt fats that are in solid form like lard. If your oils are already in liquid form such as canola oil or corn oil just heat them up to around 110 degrees. Check to make sure that the container you are using to heat the oil is is large enough to hold the oil plus the lye solution with enough room left over for stirring without splashing the solution everywhere. If you would like, you can use a separate container for mixing the oil and lye together. If you do this simply pour the warmed oil into this container prior to step 4.

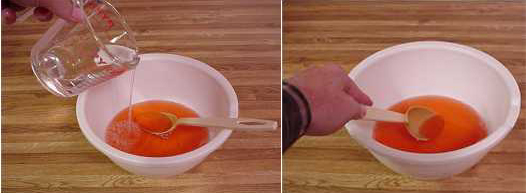

Step Four – Carefully pour the lye solution into the now 110 degree oil/fat solution. Pour in a steady, slow stream and stir slowly and constantly. Do not to splatter the solution onto yourself or others. Continue stirring. Depending upon the types of oils you are using the lye oil solution will begin to thicken or trace in 15 minutes to 3 hours. To trace means that the solution has thickened and if you drizzle some from the spoon it creates a trace on the surface. If you are using a slow trace recipe you can stir for a few minutes and then let the solution sit for 10-15 minutes and then repeat this process until a trace appears. If you used the proper amount of lye it will eventually trace or thicken.

Step Four – Carefully pour the lye solution into the now 110 degree oil/fat solution. Pour in a steady, slow stream and stir slowly and constantly. Do not to splatter the solution onto yourself or others. Continue stirring. Depending upon the types of oils you are using the lye oil solution will begin to thicken or trace in 15 minutes to 3 hours. To trace means that the solution has thickened and if you drizzle some from the spoon it creates a trace on the surface. If you are using a slow trace recipe you can stir for a few minutes and then let the solution sit for 10-15 minutes and then repeat this process until a trace appears. If you used the proper amount of lye it will eventually trace or thicken.

Step Five – When the solution begins to thicken you can add any fragrance oils or essential oils as well as any other additives such as oatmeal, pumice, coffee, herbs that your recipe calls for. Stir these ingredients into the soap and mix thoroughly. The reason these are added at trace and not before is to keep the lye from destroying them.

Step Six – Carefully pour this mixture into your molds. Your mold should be greased or sprayed with PAM. This will help the bars to release. After you pour the traced soap into your mold you should cover it with a towel to prevent the soap from cooling to fast. The mixture will stay warm for a while. Keeping it in a warm dry place and covered will help the soap to cure faster and more efficiently. This will help give you the best possible result from your batch.

Step Six – Carefully pour this mixture into your molds. Your mold should be greased or sprayed with PAM. This will help the bars to release. After you pour the traced soap into your mold you should cover it with a towel to prevent the soap from cooling to fast. The mixture will stay warm for a while. Keeping it in a warm dry place and covered will help the soap to cure faster and more efficiently. This will help give you the best possible result from your batch.

Step Seven – Let the soap harden for a day or two and then pop it out of the mold, cut it and let it age for about 3 – 6 weeks before using it. You can do a ph test and when it is at 8.5 – 10 it is ready.

Step Seven – Let the soap harden for a day or two and then pop it out of the mold, cut it and let it age for about 3 – 6 weeks before using it. You can do a ph test and when it is at 8.5 – 10 it is ready.

TIP – You can purchase soap colorants from a soap supply company or you can use crayons that are made with stearic acid (most are). To use crayons melt a small piece and add it at the trace stage. We also have soap supplies available below.