Making soap in a blender is fun and easy. It is quicker than standard cold process or hot process soapmaking and has some advantages as well as one limitation.

Before you begin you will need to decide on a soap recipe. Check our free soap recipes listed to the right. I would suggest using a formula that includes some Palm oil and/or Coconut oil. These two oils are essential if you want a hard bar of soap that lathers well. They also create a fairly quick trace time. It is recommended that you run whatever recipe you select through a lye calculator like our Soap-Calc or one of the free online SAP calculators. By doing this you can be sure that you will be using the proper amount of lye. Also, you can adjust the lye content to leave excess fat in your soap. A bar with more excess fat (over 5%) will moisturize your skin better. Bars with less than 5% excess fat will leave you feeling cleaner. A lot of this depends on your skin type. It is nice to be able to alter this characteristic with just a slight lye adjustment.

Making Soap in a Blender

The only limitation in making soap in a blender is that it does not allow for big batches of soap. 16 ounces is about the limit. However, it has four nice advantages:

1) Blending your soap mix creates a much shorter trace time. Instead of 15 – 40 minutes, it might require only minutes or even seconds depending on what type of oils you use. This means you can mix and pour a batch in much less time. It also eliminates all the stirring that must be done with cold process methods.

2) Since liquid fat and oils can be used at room temperature, there is no need for a thermometer. If you have some solid fats like lard simply heat them until they are melted and add to the blender. This means that in many cases you do not need to use a stove to heat the oils.

3) The blending process effectively whips the lye and water into the oil and fats producing a much smoother mixture. This lowers the chances of your mix separating. This lowers the number of bad batches.

4. Your soap bars will be creamier in consistency and will even float due to the air that is whipped into the solution. The final product is smoother and higher in quality.

(Use small one-pound batches only).

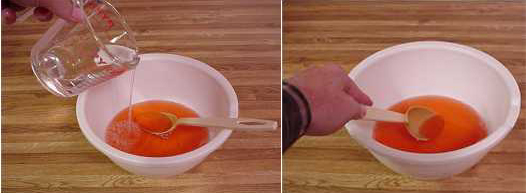

Step One – Dissolve the lye in cold water and wait until the solution cools and the mixture turns clear. At this point the lye is ready to begin converting oil to soap. It is also very caustic so make sure you are wearing goggles and gloves when handling lye. Never pour water into lye. Only pour lye INTO water.

Step Two – Carefully pour the oil into the blender. Then carefully pour the lye/water solution into the blender. The blender will of course be OFF when you are doing this. Be careful not to splash or spill the lye solution on yourself or others. Make sure you are wearing goggles and gloves.

Step Three – Lock the blender in position, secure the cover and place a towel over the top of the blender for safety. Begin blending at the lowest possible speed. Again, make sure to wear goggles when you process the soap mixture and make sure the towel is in place to avoid any accidental splashing of the lye/oil mixture. If you do this there will be almost no chance of any accidents.

Stop the blender and check the soap often to watch for what is called a thin-trace stage. This is point at which the soap mixture begins to thicken. If you were to take a spoonful and drizzle it over the mixture it would make a trace on the surface. Each time you stop the blender, wait a few seconds before removing the cover. When you remove the cover keep the towel between you and the blender just in case some soap splashes. Sometimes the soap “burps” when it stops as trapped air comes to the top. At the thin trace stage, stop the blender and stir the soap to check for tracing and to allow bubbles to escape. At this point you are trying to avoid letting the soap get too thick. If it hardens in the blender that can cause issues.

Step Four – At this point you can add any essential oils,colorants or fragrances as well as any other ingredients such as oatmeal or herbs. You add them at this point because the lye has done most of its work and will not affect the extra ingredients as much. Blend these in for a few seconds and then stop the blender.

Step Five – Carefully pour the soap into individual molds or one mold. Cover it with a blanket for insulation. Larger molds work well because the soap stays together and keeps itself warm. Cooling too fast can alter the curing process and ruin a batch. A warm, dry room is best. Let the soap set for a day or two and then after popping it out of the molds cut it and let it age for at least three weeks.

At this point your soap should be ready to use. You can check the ph level with a test strip if you wish. Between 8.5 and 10 is the goal.

Step Six – Carefully pour this mixture into your molds. Your mold should be greased or sprayed with PAM. This will help the bars to release. After you pour the traced soap into your mold you should cover it with a towel to prevent the soap from cooling to fast. The mixture will stay warm for a while. Keeping it in a warm dry place and covered will help the soap to cure faster and more efficiently. This will help give you the best possible result from your batch.

Step Six – Carefully pour this mixture into your molds. Your mold should be greased or sprayed with PAM. This will help the bars to release. After you pour the traced soap into your mold you should cover it with a towel to prevent the soap from cooling to fast. The mixture will stay warm for a while. Keeping it in a warm dry place and covered will help the soap to cure faster and more efficiently. This will help give you the best possible result from your batch. Step Seven – Let the soap harden for a day or two and then pop it out of the mold, cut it and let it age for about 3 – 6 weeks before using it. You can do a ph test and when it is at 8.5 – 10 it is ready.

Step Seven – Let the soap harden for a day or two and then pop it out of the mold, cut it and let it age for about 3 – 6 weeks before using it. You can do a ph test and when it is at 8.5 – 10 it is ready.